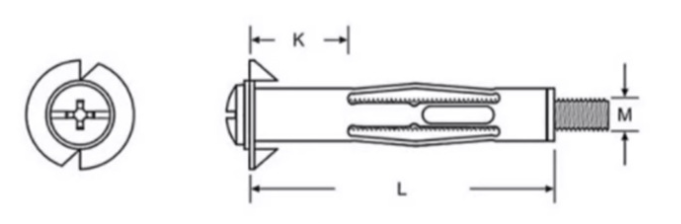

Hollow wall anchor bolts, also known as hollow wall anchors or hollow expansion screws, are mainly used in hollow walls, gypsum boards, fiberboards, plastic boards, wooden boards and other walls. They are light load anchor bolts. The heads and nuts at both ends are of two types: “welded” and “integrated”. They can be directly installed with an electric screwdriver or pulled with special tools.

Installation method:

1. The teeth on the head of the casing can be embedded in the hollow substrate, which can effectively prevent the casing from rotating in the hole during installation.

2. After installation, the expansion arm is opened behind the hollow substrate to form a large radius and large area of contact, providing a reliable

anchoring effect.

3. The matching screws can be easily removed, and the mounting parts can be repeatedly disassembled and assembled without affecting the anchoring effect.

4. Ordinary flat-blade or cross screwdrivers can be used for installation. If special installation tools are used, it can be more suitable for large-scale professional use occasions.

| Product Name | Hollow Wall Anchor |

| Material | Carbon steel, Stainless steel |

| Surface Finish | Yellow zinc, Blackened, Blue and white zinc, Dacromet |

| Colour | Yellow, Black, Blue White, White |

| Standard Number | DIN,ASME,ASNI,ISO |

| Grade | 4.8 5.8 8.8 10.9 A2-70 |

| Diameter | M4 M5 M6 M8 |

| Thread form | Coarse thread, Fine thread |

| Place of origin | Hebei, China |

| Brand | Muyi |

| Pack | Box+cardboard carton+pallet |

| The product can be customized | |

| Hollow wall anchor bolts, also known as hollow wall anchors or hollow expansion screws, are mainly used in hollow walls, gypsum boards, fiberboards, plastic boards, wooden boards and other walls. They are light load anchor bolts. The heads and nuts at both ends are of two types: "welded" and "integrated". They can be directly installed with an electric screwdriver or pulled with special tools. Installation method: 1. The teeth on the head of the casing can be embedded in the hollow substrate, which can effectively prevent the casing from rotating in the hole during installation. 2. After installation, the expansion arm is opened behind the hollow substrate to form a large radius and large area of contact, providing a reliable anchoring effect. 3. The matching screws can be easily removed, and the mounting parts can be repeatedly disassembled and assembled without affecting the anchoring effect. 4. Ordinary flat-blade or cross screwdrivers can be used for installation. If special installation tools are used, it can be more suitable for large-scale professional use occasions. |

|

Please enter your email address and we will reply to your email.