1.hexagon socket bolts ISO 7380 are widely used both indoors and outdoors. Outdoor applications are mostly for building installations, bridges and roads, and power facilities; indoor applications are mostly for mechanical equipment, medical equipment, and electronic equipment.

2.When hexagon socket bolts ISO 7380 are used in electronic equipment, medical equipment, and other places, stainless steel hexagon socket bolts ISO 7380 are generally selected because the surface color of stainless steel is more beautiful and the corrosion resistance is better, which can keep the machine beautiful for a long time. If it is a mechanical equipment with large vibration, it is recommended to choose high-strength hexagonal bolts.

| Product Name | Hexagon socket bolts ISO 7380 |

| Material | Carbon steel, Stainless steel |

| Surface Finish | Yellow zinc, Blackened, Blue and white zinc, Bleached |

| Colour | Yellow, Black, Blue White, White |

| Standard Number | DIN933 |

| Grade | 4.8 5.8 8.8 10.9 A2-70 |

| Diameter | M3 M4 M5 M6 M8 M10 M12 M16 |

| Thread form | Coarse thread, Fine thread |

| Place of origin | Hebei, China |

| Brand | Muyi |

| Pack | Box+cardboard carton+pallet |

| The product can be customized | |

| 1.hexagon socket bolts ISO 7380 are widely used both indoors and outdoors. Outdoor applications are mostly for building installations, bridges and roads, and power facilities; indoor applications are mostly for mechanical equipment, medical equipment, and electronic equipment. 2.When hexagon socket bolts ISO 7380 are used in electronic equipment, medical equipment, and other places, stainless steel hexagon socket bolts ISO 7380 are generally selected because the surface color of stainless steel is more beautiful and the corrosion resistance is better, which can keep the machine beautiful for a long time. If it is a mechanical equipment with large vibration, it is recommended to choose high-strength hexagonal bolts. |

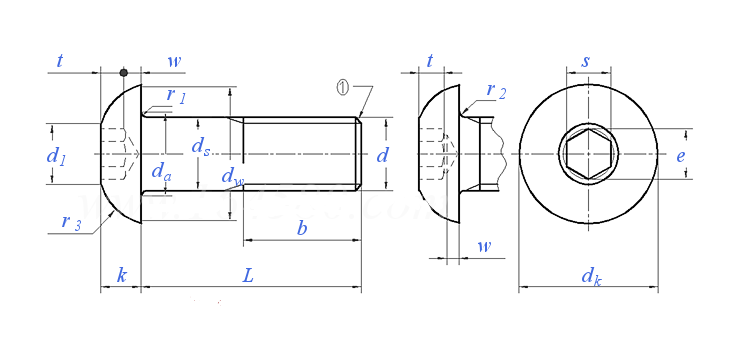

|

| Thread Spec d |

M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | |

| P | Thread | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 |

| b | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 44 | |

| da | Max | 3.6 | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 17.7 |

| dk | Max | 5.7 | 7.6 | 9.5 | 10.5 | 14 | 17.5 | 21 | 28 |

| Min | 5.4 | 7.24 | 9.14 | 10.07 | 13.57 | 17.07 | 20.48 | 27.48 | |

| d1 | 2.6 | 3.8 | 5 | 6 | 7.7 | 10 | 12 | 16 | |

| ds | Max | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 15.73 | |

| dw | Min | 4.97 | 6.66 | 8.41 | 9.26 | 12.48 | 15.7 | 18.84 | 25.28 |

| e ③ | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 |

| k | Max | 1.65 | 2.2 | 2.75 | 3.3 | 4.4 | 5.5 | 6.6 | 8.8 |

| Min | 1.4 | 1.95 | 2.5 | 3 | 4.1 | 5.2 | 6.24 | 8.44 | |

| r3 | Max | 3.7 | 4.6 | 5.75 | 6.15 | 7.95 | 9.8 | 11.2 | 15.3 |

| Min | 3.3 | 4.2 | 5.25 | 5.65 | 7.45 | 9.2 | 10.5 | 14.5 | |

| r1 | Min | 0.1 | 0.2 | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 |

| r2 | Min | 0.3 | 0.4 | 0.45 | 0.5 | 0.7 | 0.7 | 1.1 | 1.1 |

| s | Nominal | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 |

| Max | 2.08 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | |

| t | Max | 1.2 | 1.65 | 2.12 | 2.26 | 3.05 | 3.75 | 4.61 | 6.19 |

| Min | 1.04 | 1.3 | 1.56 | 2.08 | 2.6 | 3.12 | 4.16 | 5.2 | |

| w | Min | 0.2 | 0.3 | 0.38 | 0.74 | 1.05 | 1.45 | 1.63 | 2.25 |

| N | 8.8 ① | 3220 | 5620 | 9120 | 12900 | 23400 | 37100 | 54000 | 101000 |

| 10.9 ① | 4190 | 7300 | 11800 | 16800 | 30500 | 48300 | 70200 | 130000 | |

| 12.9/12.9 ① | 4910 | 8640 | 13900 | 19700 | 35800 | 56600 | 82400 | 154000 | |

| 70 ② | 2820 | 4920 | 7940 | 11300 | 20600 | 32500 | 47200 | 88000 | |

| 80 ② | 3220 | 5620 | 9120 | 12900 | 23400 | 37100 | 54000 | 101000 | |

Please enter your email address and we will reply to your email.