1. Mechanical manufacturing: Hexagonal locking thin nuts are mainly used to connect and fix various mechanical components, such as screws, flanges, bearings, and camshafts, to ensure the normal operation of machines.

2. Automotive manufacturing: In the automotive manufacturing process, hexagonal locking thin nuts are used to connect and secure various automotive components such as engines, axles, and suspensions to ensure the safety and stability of the vehicle.

3. Construction field: Hexagonal locking thin nuts are widely used in the assembly of steel structures, such as bridges, factories, etc. They are lightweight and have good anti loosening properties, which can ensure the stability and safety of steel structures during use.

4. Electronic devices: In the field of electronic product manufacturing, such as mobile phones, computers, etc., hexagonal locking thin nuts are used to fix and connect various components, such as batteries, motherboards, displays, etc., to save space and reduce weight.

5. Home decoration: In the field of home decoration, hexagonal locking thin nuts are commonly used in the assembly of furniture, toys and other products, which can not only play a fixing role but also maintain a clean appearance.

6. General field: Hexagonal locking thin nuts are also widely used in the production and manufacturing processes of various mechanical equipment, instruments, household appliances, etc.

| Product Name | DIN985 Hex Lock Nut with blue |

| Material | Carbon steel, Stainless steel |

| Surface Finish | Yellow zinc ,Blue white zinc,Original color,White zinc,Decolourize,Dacromet |

| Colour | Yellow, Blue White, White |

| Standard Number | DIN985 |

| Grade | 4 8 10 A2-70 |

| Diameter | M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30 M33 M36 M39 M45 M48 |

| Thread form | Coarse thread |

| Place of origin | Hebei, China |

| Brand | Muyi |

| Pack | Box+cardboard carton+pallet |

| The product can be customized | |

| 1. Mechanical manufacturing: Hexagonal locking thin nuts are mainly used to connect and fix various mechanical components, such as screws, flanges, bearings, and camshafts, to ensure the normal operation of machines. 2. Automotive manufacturing: In the automotive manufacturing process, hexagonal locking thin nuts are used to connect and secure various automotive components such as engines, axles, and suspensions to ensure the safety and stability of the vehicle. 3. Construction field: Hexagonal locking thin nuts are widely used in the assembly of steel structures, such as bridges, factories, etc. They are lightweight and have good anti loosening properties, which can ensure the stability and safety of steel structures during use. 4. Electronic devices: In the field of electronic product manufacturing, such as mobile phones, computers, etc., hexagonal locking thin nuts are used to fix and connect various components, such as batteries, motherboards, displays, etc., to save space and reduce weight. 5. Home decoration: In the field of home decoration, hexagonal locking thin nuts are commonly used in the assembly of furniture, toys and other products, which can not only play a fixing role but also maintain a clean appearance. 6. General field: Hexagonal locking thin nuts are also widely used in the production and manufacturing processes of various mechanical equipment, instruments, household appliances, etc. |

|

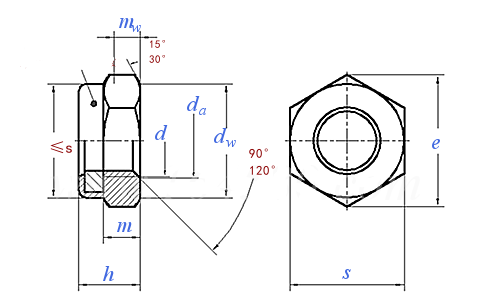

| Thread Spec D |

M3 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | ||

| P | flight lead | Coarse thread | 0.5 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 |

| Fine thread1 | / | / | / | / | / | 1 | 1 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | ||

| Fine thread2 | / | / | / | / | / | / | 1.25 | 1.25 | / | / | 1.5 | 1.5 | 1.5 | / | / | / | / | / | / | / | / | / | ||

| da | min | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | |

| max | 3.45 | 4.6 | 5.75 | 6.75 | 7.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | 21.6 | 23.7 | 25.9 | 29.1 | 32.4 | 35.6 | 38.9 | 42.1 | 45.4 | 48.6 | 51.8 | ||

| dw | min | 4.6 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | 24.9 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.6 | 51.1 | 55.9 | 60.6 | 64.7 | 69.4 | |

| e | min | 6.01 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 72.09 | 76.95 | 82.6 | |

| h | max=nominal | 4 | 5 | 5 | 6 | 7.5 | 8 | 10 | 12 | 14 | 16 | 18.5 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | |

| min | 3.7 | 4.7 | 4.7 | 5.7 | 7.14 | 7.64 | 9.64 | 11.57 | 13.3 | 15.3 | 17.66 | 18.7 | 20.7 | 22.7 | 25.7 | 28.7 | 31.4 | 34.4 | 37.4 | 40.4 | 43.4 | 46.4 | ||

| m | min | 2.4 | 2.9 | 3.2 | 4 | 4.7 | 5.5 | 6.5 | 8 | 9.5 | 10.5 | 13 | 14 | 15 | 15 | 17 | 19 | 22 | 25 | 27 | 29 | 32 | 36 | |

| mw | min | 1.65 | 2.2 | 2.75 | 3.3 | 3.85 | 4.4 | 5.5 | 6.6 | 7.7 | 8.8 | 9.9 | 11 | 12.2 | 13.2 | 14.8 | 16.5 | 18.2 | 19.8 | 21.5 | 23.1 | 24.8 | 26.5 | |

| s | max=nominal | 5.5 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | |

| min | 5.32 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | 26.16 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.8 | 68.1 | 73.1 | ||

| 1000 pcs/weight KG |

0.5 | 1 | 1.4 | 2.4 | 3 | 5.1 | 10.6 | 17.2 | 26 | 34 | 45 | 65 | 75 | 100 | 162 | 212 | 317 | 415 | 499 | 628 | 771 | 998 | ||

Please enter your email address and we will reply to your email.