Hex nuts are used in conjunction with bolts and screws to primarily connect and tighten mechanical components. Hexagonal nuts of different types and grades are suitable for different occasions to meet different precision and surface treatment requirements. Widely applicable, with strong fastening force, suitable for occasions requiring large operating space.

| Product Name | DIN934 Hex Nut |

| Material | Carbon steel, stainless steel |

| Surface Finish | Blue white zinc, Blackened, Yellow zinc, Natural color, Decolourize, White zinc |

| Colour | Blue white, Black, Yellow, White |

| Standard Number | DIN934 |

| Grade | 4 6 8 |8| 10 12 A2-70 A4-70 |

| Diameter | M2 M2.5 M2.6 M3 M3.5 M4 M5 M6 M7 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30 M33 M36 M39 M42 M45 M48 M52 M56 |

| Thread form | Coarse thread, Medium thread, Fine thread, Extremely fine thread, Reverse thread, Positive thread |

| Place of origin | Hebei, China |

| Brand | Muyi |

| Pack | Box+cardboard carton+pallet |

| The product can be customized | |

| Hex nuts are used in conjunction with bolts and screws to primarily connect and tighten mechanical components. Hexagonal nuts of different types and grades are suitable for different occasions to meet different precision and surface treatment requirements. Widely applicable, with strong fastening force, suitable for occasions requiring large operating space. | |

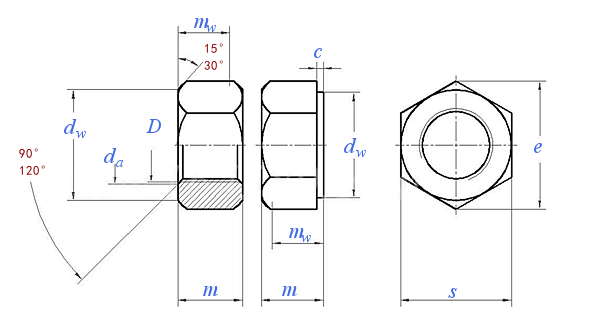

| Thread Spec D |

M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | (M45) | M48 | (M52) | M56 | |

| P | flight lead | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | 5.5 |

| c | max | 0.2 | 0.2 | 0.3 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |

| da | max | 1.84 | 2.3 | 2.9 | 3.45 | 4 | 4.6 | 5.75 | 6.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | 23.7 | 25.9 | 29.1 | 32.4 | 35.6 | 38.9 | 42.1 | 45.4 | 48.6 | 51.8 | 56.2 | 60.5 |

| min | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | 52 | 56 | |

| dw | min | 2.4 | 3.1 | 4.1 | 4.6 | 5 | 5.9 | 6.9 | 8.9 | 11.6 | 14.6 | 16.6 | 19.6 | 22.5 | 24.9 | 31.4 | 33.3 | 38 | 42.8 | 46.6 | 51.1 | 55.9 | 60 | 64.7 | 69.5 | 74.2 | 78.7 |

| e | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | 23.36 | 26.75 | 29.56 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 |

| m | max | 1.3 | 1.6 | 2 | 2.4 | 2.8 | 3.2 | 4.7 | 5.2 | 6.8 | 8.4 | 10.8 | 12.8 | 14.8 | 15.8 | 19.4 | 21.5 | 23.8 | 25.6 | 28.7 | 31 | 33.4 | 34 | 36 | 38 | 42 | 45 |

| min | 1.05 | 1.35 | 1.75 | 2.15 | 2.55 | 2.9 | 4.4 | 4.9 | 6.44 | 8.04 | 10.37 | 12.1 | 14.1 | 15.1 | 18.1 | 20.2 | 22.5 | 24.3 | 27.4 | 29.4 | 31.8 | 32.4 | 34.4 | 36.4 | 40.4 | 43.4 | |

| mw | min | 0.8 | 1.1 | 1.4 | 1.7 | 2 | 2.3 | 3.5 | 3.9 | 5.2 | 6.4 | 8.3 | 9.7 | 11.3 | 12.1 | 14.5 | 16.2 | 18 | 19.4 | 21.9 | 23.5 | 25.4 | 25.9 | 27.5 | 29.1 | 32.3 | 34.7 |

| s | max=nominal | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 |

| min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | |

Please enter your email address and we will reply to your email.