1. DIN7991 adopts countersunk head design, countersunk head screw design so that it can be flush on the surface, will not protrude, increase the aesthetic. At the same time, the hex provides better torque transfer, reducing the possibility of sliding and damage. When the high strength grade (usually 10.9 grade) made of alloy steel is used, it has good tensile and shear resistance. DIN7991 screws make screws easier to install and tighten, and are suitable for applications where frequent disassembly is required

2. Hexagon flat head screw DIN7991 is widely used in many fields, such as automobiles and automobile new energy field, military aerospace field, shipbuilding heavy industry field, medical equipment field, food machinery field, electronic communication equipment field and wind power field.

| Product Name | DIN7991 Hex socket countersunk head screws |

| Material | Carbon steel, Stainless steel |

| Surface Finish | Yellow zinc, Blackened, Blue and white zinc, Bleached |

| Colour | Yellow, Black, Blue White, White |

| Standard Number | DIN7991 |

| Grade | 4.8、8.8、10.9、12.9、A2-70、A4-70 |

| Diameter | M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 |

| Thread form | Coarse thread, Medium thread, Fine thread |

| Place of origin | Hebei, China |

| Brand | Muyi |

| Pack | Box+cardboard carton+pallet |

| The product can be customized | |

| 1. DIN7991 adopts countersunk head design, countersunk head screw design so that it can be flush on the surface, will not protrude, increase the aesthetic. At the same time, the hex provides better torque transfer, reducing the possibility of sliding and damage. When the high strength grade (usually 10.9 grade) made of alloy steel is used, it has good tensile and shear resistance. DIN7991 screws make screws easier to install and tighten, and are suitable for applications where frequent disassembly is required 2. Hexagon flat head screw DIN7991 is widely used in many fields, such as automobiles and automobile new energy field, military aerospace field, shipbuilding heavy industry field, medical equipment field, food machinery field, electronic communication equipment field and wind power field. |

|

| Thread Spec D |

M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | |

| P | thread pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

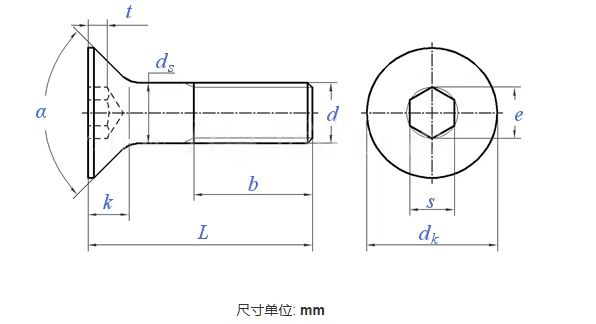

| α | tol.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125 | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | max=nominal | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | max=nominal | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | nominal | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | max=nominal | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Please enter your email address and we will reply to your email.