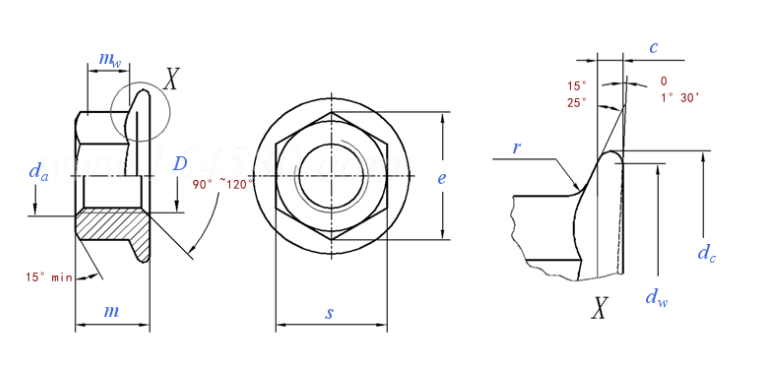

1.DIN6923 hexagon flange nut and general hexagon nut compared with the size and thread specifications are basically the same, but more than the hexagon nut with one ring flange, equivalent to the washer and nut are integrated, and there is a ring of non-slip tooth grain on the flange surface, also known as tooth flange nut.

2. Widely used : hexagon flange nuts mainly play a role in increasing the contact surface with the workpiece, mostly used in pipelines, fasteners and some stamping parts and casting parts. The flange face of DIN6923 flange nut itself has the function of anti-slip and stop, and it does not need to add flat pad and spring pad when assembling, which is more convenient to use

| Product Name | DIN 6923 Flange nuts |

| Material | Carbon steel, Stainless steel |

| Surface Finish | Yellow zinc, Blackened, Blue and white zinc, Bleached |

| Colour | Yellow, Black, Blue White, White |

| Standard | DIN 6923 |

| Grade | 4.8/6.8/8.8/10.9/12.9 ; A2-70 |

| Diameter | M1.4 M1.6 M2 M2.5 M3 M4......M80 M90 M100 |

| Thread form | Coarse thread, Medium thread, Fine thread |

| Place of origin | Hebei, China |

| Brand | Muyi |

| Pack | Box+cardboard carton+pallet |

| The product can be customized | |

| 1.DIN6923 hexagon flange nut and general hexagon nut compared with the size and thread specifications are basically the same, but more than the hexagon nut with one ring flange, equivalent to the washer and nut are integrated, and there is a ring of non-slip tooth grain on the flange surface, also known as tooth flange nut.

2. Widely used : hexagon flange nuts mainly play a role in increasing the contact surface with the workpiece, mostly used in pipelines, fasteners and some stamping parts and casting parts. The flange face of DIN6923 flange nut itself has the function of anti-slip and stop, and it does not need to add flat pad and spring pad when assembling, which is more convenient to use |

|

| Thread size D |

M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | ||

| P | Screw pitch | Coarse teeth | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 |

| Fine Tooth 1 |

/ | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Fine Tooth 2 |

/ | / | / | 1 | 1.25 | / | / | / | ||

| C | Min | 1 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | |

| da | Min | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

| Max | 5.75 | 6.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 21.6 | ||

| dc | Max | 11.8 | 14.2 | 17.9 | 21.8 | 26 | 29.9 | 34.5 | 42.8 | |

| dw | Min | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |

| e | Min | 8.79 | 11.05 | 14.38 | 16.64 | 20.03 | 23.36 | 26.75 | 32.95 | |

| m | Max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

| Min | 4.7 | 5.7 | 7.6 | 9.6 | 11.6 | 13.3 | 15.3 | 18.9 | ||

| mw | Min | 2.2 | 3.1 | 4.5 | 5.5 | 6.7 | 7.8 | 9 | 11.1 | |

| s | Max | 8 | 10 | 13 | 15 | 18 | 21 | 24 | 30 | |

| Min | 7.78 | 9.78 | 12.73 | 14.73 | 17.73 | 20.67 | 23.67 | 29.67 | ||

| r | Max | 0.3 | 0.36 | 0.48 | 0.6 | 0.72 | 0.88 | 0.96 | 1.2 | |

Please enter your email address and we will reply to your email.